With your medical device development underway, it's important to keep packaging design in mind as you hit key milestones and stage gates. In the grand scheme of your device development, packaging is one of many on the to do list. And although it is near the end of the process in terms of manufacturing and assembly, it's important to consider it throughout your device design and development.

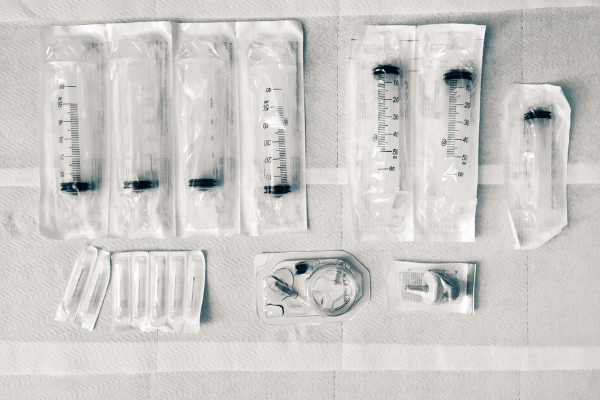

Packaging serves as the protective delivery mechanism for your device - and therefore needs great care and attention. As you navigate your device design process, keep these five packaging considerations in mind to ensure your device can be delivered safely and securely.

#1: Device Protection

We're going to go ahead and state the obvious here. Your device needs to be able to get from you or your warehouse to your customer, sans damage. If we just think about the device itself arriving in one piece (we'll talk about it's sterility in a moment), what type of packaging is needed to ensure safe transport and delivery?

One of the decisions associated with this design consideration is the packaging platform. In terms of the most common platforms seen in the medical device industry, pouches, bags and forming films are typically used for more commodity products that don't have high product protection requirements. On the other hand, die cut lids, thermoforming trays, and laminations are used to provide enhanced protection at various levels.

#2: Medical Device Sterilization

Next on our list, but in no particular order, is your device sterilization process and requirements. Your package needs utilize a material that is compatible with your sterilization method - Ethylene Oxide (EO), Radiation, Steam, or other. From a design perspective, your package needs to survive sterilization, then maintain sterility and serve as a protective barrier against outside factors it comes into contact with post-sterilization.

#3: Barrier Requirements

More and more often medical devices are specifying additional barrier requirements to protect their device against additional aggressors post-sterilization, including:

- Oxygen

- UV Light

- Solvents

- Moisture

- Odor/Vapor

- Acids/Bases

- Microbial

This design consideration is largely addressed through material selection, once again. If you are needing to protect your device against one or more of the above factors, your package platform will need to align with what your selected material can accommodate.

#4: Product Accessibility

While device protection is key, easy accessibility is also key if your device is going to be bought and used effectively. Your package design should make it easy for your end users to access within their working/usage environment. This likely means ensuring sterility throughout the opening of the package; but additional circumstances should also be addressed. Think about the situations where your end users will be accessing your device and how your packaging can accommodate environmental, emotional, and physical factors present at the time of use.

To be really, really excellent in terms of design, [...] we need to bring equal voice to the users needs. The users' functional capabilities and the expectations about what they need to do with the product also need to drive design decisions.

Laura Bix

Assistant Dean for Teaching, Learning and Academic Analytics & School of Packaging Professor at Michigan State University

Material again is an important variable in this equation. Clear packaging is often preferred to aid easy and quick device identification.

#5: Packaging Recyclability

A trend that has been growing in priority these last few years is the sustainability of packaging in medical environments. A lot of material is used to protect and transport medical devices, and unfortunately a lot of if ends up in our trash system because of the classification of medical waste and lack of recycling programs in place. There is a lot of work and research being done here, but there are a few things device developers and packaging engineers can consider today.

- Reduce the footprint and amount of material used in your packaging

Consider new package designs or configurations to optimize the material usage without compromising your device safety and security. - Use material that flows into existing recycling streams

Eliminate this hurdle by using material that can be recycled via current processes

A Good Start

There are many factors to consider when packaging your medical device; hopefully this list gives you a good place to start. Develop smart packaging requirements and partner with a reputable packaging supplier - then you'll be on the best track to designing and manufacturing a package suited to your device needs.